The plantations

According to botanists the cocoa tree grew wild as early as 4000 years B.C. in the Amazon River Basin. The first to cultivate cocoa were probably the Mayas who used to prepare a tonic, a fortifying drink using the cocoa beans.

When Christopher Columbus discovered America, cocoa beans were used as currency. After having tasted the delicious drink he decided to introduce it to Isabel of Castille, Queen of Spain. It was appreciated so much that very soon it became known in all the noble courts of Europe.

In the plantations, the conditions of the natural forest are recreated with tall trees to give the shade required for the good growth of the cocoa trees, which are delicate and do not tolerate direct sunlight and temperature variations.

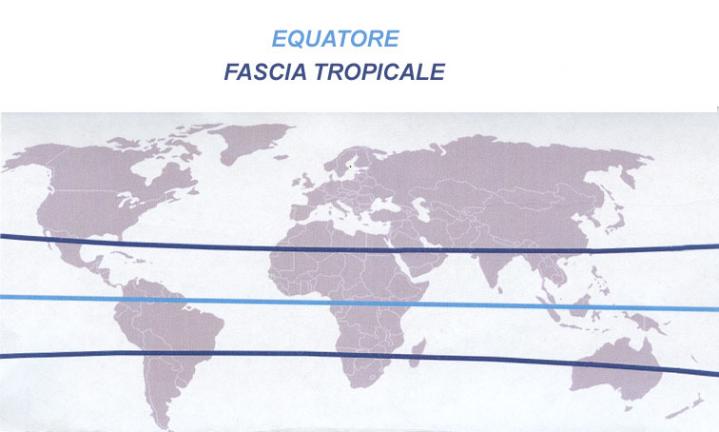

Their natural habitat is in fact tropical, with temperatures between 20° and 30°.

The ideal altitude is around 400 metres.

Today cocoa is cultivated in 45 different countries. The world production totals around 3.000.000 tons, of which

65-70% from Africa: Ivory Coast, Ghana, Nigeria, Camerun;

12-13% from Central/Latin America: Colombia, Ecuador, Brasile, Messico, Guatemala, Perù, Cuba, Tahiti, Domenican Repubblic;

17% from South-East Asia: Indonesia, Malaysia, New Guinea.

Botanical aspects

Each year thousands of small white or yellow-pink flowers blossom on the cocoa tree. Many of these wither and die. Only 1% become fruit known as the “Cocoa pod”. The cocoa pods grow directly on the trunk and the main branches of the tree.

There are three varieties of cocoa:

- the CRIOLLO type, which produces a very fine type of cocoa, originally comes from Central America and Mexico. It is very fragile and sensitive and can be recognised by its white colour and fresh beans. It accounts for no more than 2% of the entire world production.

- the FORASTERO type has violet beans and green cocoa pods which become yellow/pink when they are ripe. It is native to Amazonia and forms 80% of the world cocoa production.

- the TRINITARIO type is hybrid between the two types. It is native to Trinidad and represents 18% of the world production.

Harvesting and fermentation

The cocoa pods are picked by hand, with the greatest care. The tree, which begins producing fruit after 3-4 years and becomes fully mature after 6 years, can produce up to 80 cocoa pods per year for about forty years. The yield per hectare rarely exceeds 1000 kilos of cocoa beans.

Experience and skill are required to cut the cocoa pods without damaging the beans contained within. Each pod, wich measures 15/20 cm in length, contains 30/40 beans and an abundance of sugary pulp. Once the pods have been picked and opened, the beans and pulp are extracted and piled into crates or baskets (traditionally on banana leaves) and left to rest 5-6 days. During this time a number of fermentation processes begin: alcoholic, lactic, acetic.

The fermentation has three important functions:

Ø The elimination of the pulp;

Ø The beans are prevented from germinating;

Ø The precursors of the aromas are created, i.e. those elements which determine the aroma, the taste, the fullness and the complexity of the aromas of a good chocolate during the subsequent phases (roasting, conching, etc.).

Drying and the control of quality

After fermentation the beans are sun-dried for as long as 10/12 days and thus lose their water content which is originally about 7%. This makes it possible to store the cocoa beans for very long periods. The drying process is also necessary in order to stop the fermentation process. If this continues for too long, it can in fact cause an excessive level of acidity and consequently damage the quality of the cocoa.

As with all valuable products, the cocoa beans undergo a very accurate quality control which is carried out both by the grower and the processing factory, after which they are put into jute bags and shipped to destination.

Upon the arrival of the cocoa at the chocolate factory the bags are emptied and the beans are stored in silos. This is where the manufacturing process of the chocolate begins.

Production: cocoa mass

Ø Cleaning – The cocoa is cleaned to remove any foreign bodies and selection takes place by separating the the whole beans from the broken one. Only the whole beans continue the process.

Ø Pre-toasting – The beans undergo a strong radiation at 400° for 100 seconds which facilities the removal of the cocoa bean shell.

Ø Broyage – The beans are crushed into small pieces referred to as GRAI N and at the same time the shells are eliminated.

Ø Alcalinisation – The grain undergoes a bath in water to which potassium carbonate may be added in order to reduce the natural acidity of the cocoa.

Ø Roasting - The grain is toasted with hot air at a temperature between 100/120°. The roasting process takes about 30 minutes to ensure that the grain is evenly toasted in order to allow the finest aromas of the cocoa to develop.

Ø Milling – The grain is milled in a pin-mill which turns it into a product referred to as cocoa liquor or cocoa paste.

Production: cocoa butter and powder

Ø Pressing – the cocoa paste is pressed in hydraulic presses which extract the fatty matter, the cocoa butter, the dry part which remains from the pressing of the cocoa paste is the cocoa presscake.

Ø Filtration – The cocoa butter is filtered using paper filters which retain any impurities.

Ø Deodorising – The cocoa butter is subjected to a deodorising process. A part of the volatile acids is extracted by means of a high-pressure steam jet, to give the butter a sweeter and less acidic taste.

Ø Pulverisation – The presscake is first crushed coarsely and then finely ground to form a powder. At this stage it is ready to be packaged for sale.

Production: chocolate

Ø Blending – The ingredients are selected and mixed in proportions according to the specific recipe and type of chocolate desired: milk, white, dark, gianduja.

Ø Refining – Large refining drums crush and cut the chocolate paste to obtain particles measuring no more than 18 microns.

Ø Conching – The conching process may take many hours and is carried out for different purposes:

- To create a perfect blend of the various components.

- To reduce the acid and astringent flavours.

- To extract any remaining humidity which is thus lowered to no more than 0,5-0,8%.

In this phase, usually a small part of soya lecithin 0,3% is added as a liquifying agent and emulsifier plus a tiny amount of vanilla to add flavour.

Ø Tempering – Before being moulded, the chocolate paste has to undergo a heat treatment referred to as tempering, during which the chocolate is first cooled to 26-28°C and subsequently reheated to 29-32°C. This is essential for the cocoa butter to solidify in the stable crystalline form. Only in this way can the chocolate be processed, taking up a shiny appearance and a correct form, crisp snap in addition to excellent storage properties.

Ø Moulding – The tempered chocolate is poured into special moulds of different shapes (bars, praline, chocolate eggs, etc.) and is then solidified in large cooling tunnels after which the chocolate is easily removed from the moulds.

Ø Packaging – The solid chocolate can now be wrapped and packaged in the most appealing and imaginative ways.

|